|

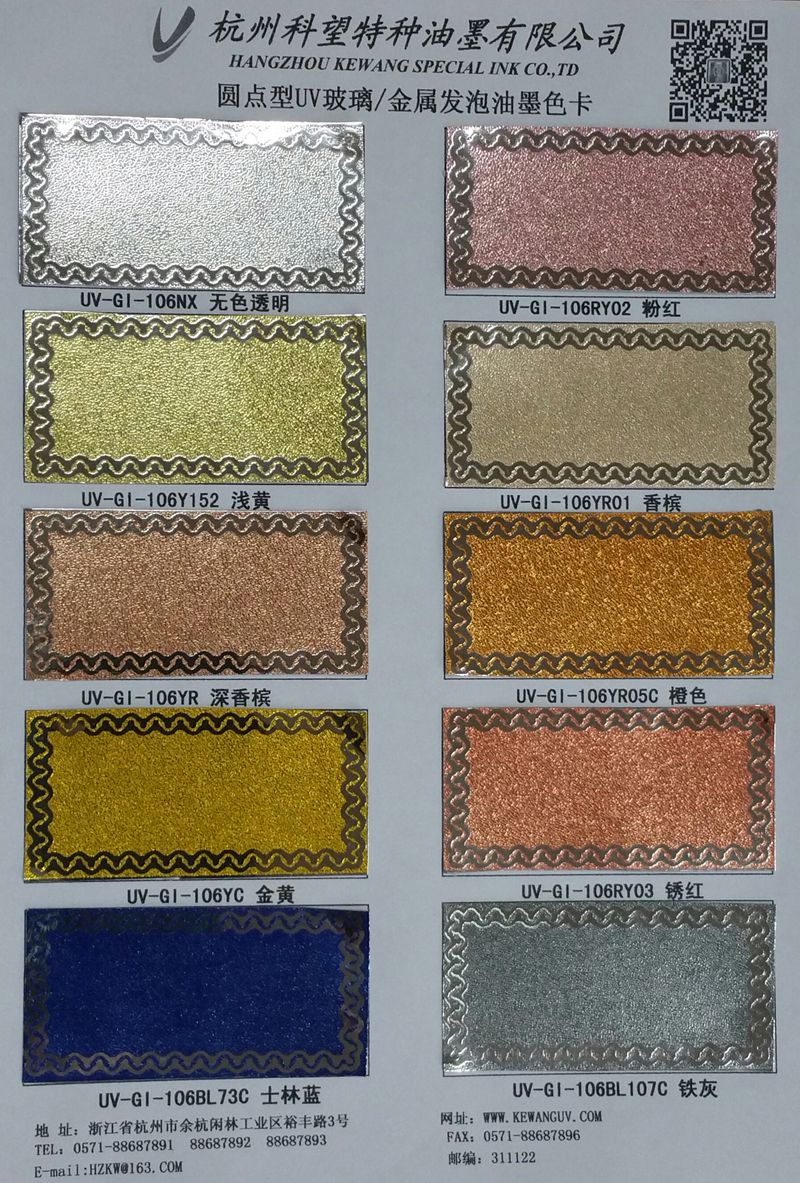

圆点型UV玻璃/金属发泡油墨 UV-GM-106NX特性与用途: 最新开发的光固金属发泡油墨UV-GM-106NX又叫圆点型发泡油墨,不同于传统的UV丝印发泡油墨花纹,其自然、美丽、奇特,立体感强,装饰性佳,墨层表面硬度高,耐刮性佳,可用于印刷镜面金属或玻璃等刚性底材,如镜面铝、铜、不锈钢等。 与一般的UV发泡油墨(又叫泡沫油墨)相比,圆点型发泡油墨UV-GM-106NX固化膜表面硬度高,附着力强,耐刮性好,可用于制作各种高档金属或玻璃工艺品、标牌、面板、装饰画等,亦可印刷于处理的PET薄膜、PVC、PC、 ABS等塑料基材上。 该油墨丝印滑爽不粘网,性能稳定,丝印后即使五分钟不光固化,油墨花纹仍能保持稳定。 技术指标: 型 号:UV-GM-106NX 粘 度:3000-3700CPS/25℃ 丝网目数:100-200目 光固速度:高压汞灯 80W/cm×2只,5-10米/分 贮存期(Shelf Life):大于6个月(more than 6 months) 使用工艺流程: 玻璃清洗干净、烘干—油墨中加21#添加剂—印刷发泡油墨—UV固化—热处理(150度/5-10分钟)

注意事项 : 印刷UV发泡油墨前,必须将玻璃清洗干净、烘干水分备用,否则玻璃表面残留的赃物或水分会影响油墨的附着牢度。 印刷前在油墨中添加21#添加剂,是为了提高油墨的耐水性和附着力,以保证玻璃在真空镀镜前水洗或成品裁切时,发泡图案不会产生脆裂或脱落。为避免浪费,建议用多少油墨,临时配多少,不要多配。加入了添加剂的UV油墨应尽快用完,否则油墨的耐水性会变差。 使用前请高速搅拌3-5分钟,至油墨由半透明变成乳白色。印刷UV发泡油墨时,丝网目数一般为100-180目,刮印速度不要太快,丝网的张力要够大。UV发泡油墨不会挥发,也不会堵网,印刷时一般不需要加稀释剂,若天气较冷,油墨变粘,可加入5-10% UV-306专用稀释剂。 丝印好发泡油墨的玻璃,必须尽快光固化,一保证发泡花纹稳定一致。否则会导致花纹疏密有别。 UV固化条件:2只80瓦/厘米的高压汞灯,速度一般为2-5米/分钟。 热处理:为了增加油墨对玻璃的牢度和表面硬度,UV光固化后需对玻璃进行加热处理,加热处理条件:150度/5-10分钟。有红外线烘道的公司可直接送入烘道热处理,温度越高,加热时间可相应缩短。 Special features and application: UV curable puff ink, UV-GM-106NX, has a pattern like coral, foam, and wrinkles, which is beautiful, curious and natural. In comparison with other common UV curable puff ink, it has a highly hard ink layer, shows good adhesion and scuff resistance. The ink can be printed smoothly, and has stable performance. The pattern can be kept for more than 5 minutes after printing.

Specifications: Produce Code: UV-GM-106NX Viscosity (25℃/CPS): 3000-3700 Screen Mesh: 100-200 Speed of Curing: High Pressure Mercury Lamp(80 W/cm×2), 5-10 m/min Shelf Life: More Than 6 Months

Produce process: Clear and dry the glass→Add 21# agent(about 2 %)→Screen printing→UV curing→Heat treating(150 ℃/5-10 min)

Notes: 1、 It is important to add 21# agent to the ink before printing, in order to improve the adhesion and water resistance. Besides, the ink mixed with 21# should be used up as soon as possible. Otherwise it may exhibit poor adhesion and water resistance. 2、 What is the most important thing is that the ink has to be mixed well for 3-5 minuters untill the color become white before printing. 3、Thinner is not necessary in general. If it is cold and the viscosity of ink become large, 5-10 % thinner, UV-306, can be added. 4、 The ink should be cured as quickly as possible after printing.

|

分享到:

Phone: 400-000-0000

E-mail: 123456@12a3.com

Adress: 北京市朝阳区xx大厦1001

Copyright @ 2018 . All rights reserved.